Fly-leads and cross-board connections have now been wired up using Leo Fender approved colours. Old Leo must have found a good cheap source of yellow wire from somewhere because he used plenty of it in his amps!

Ready to start mounting and wiring up all of the components into the chassis.

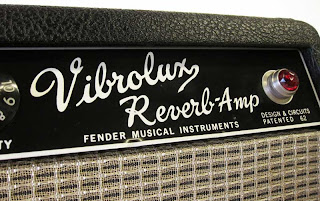

Fender Vibrolux Reverb Project

Documenting my first guitar amplifier build, a clone of the renowned Fender "Blackface" Vibrolux Reverb (AA964) – 35 Watts of tonal goodness through two 10 inch speakers.

Sunday, 22 April 2012

Test fitting the hardware into the chassis

Transformers and valve sockets have been temporarily mounted into the chassis to get a feel for the wire routing and fly-lead lengths before I start to cut and solder. I will also have to drill some additional holes to mount the circuit boards so wanted to mark these out.

My "advisory team" at AGGH have made me promise to remove everything before I start drilling any more holes in the chassis as stray pieces of metal cuttings have a habit of finding their way into and across components causing havoc. Good advice.

|

| Outside of chassis. (Clockwise L to R: reverb driver, filter capacitor board, output transformer, choke, power transformer, 8-pin rectifier and output valve sockets, preamp valve sockets) |

|

| Inside of chassis. Main eyelet board and bias supply board placed to check wiring distances and to mark holes to be drilled. Valve pins are numbered to help my ageing eyesight! |

Friday, 20 April 2012

Drilling the chassis mounting holes

A bit of angst lining up the chassis with the cabinet to drill the mounting holes. I don't want the cabinet top to look like Swiss cheese so I rigged up various bits and pieces to help align everything.

Close enough for rock and roll.

Solder fumes start to fill the air

The workbench is tidy and ready for some mayhem. Based on my past form with projects it will rapidly degenerate to an advanced state of chaos over the next few weeks.

The eyelet boards have been stuffed with components and soldered up. So far so good.

|

| Main component board - old school electronics

I still need to cut and solder the hookup wire to the main board but will leave this until I test fit everything in the chassis.

|

|

| Filter capacitor board |

|

| Bias supply board

I bought a second hand 60-Watt Goot soldering station from eBay. I thought my cheapo 35-Watt iron was good until I started using this. Heats up really quickly and maintains constant temperature. Money well spent.

|

Sunday, 15 April 2012

Chassis Cradle

I was hoping to get started over the Easter break but was still waiting on some parts to arrive.

Instead I put together this chassis cradle from plans I found online at Modulus Amplification.

Instead I put together this chassis cradle from plans I found online at Modulus Amplification.

Saturday, 14 April 2012

What's in the box

My Blackface Vibrolux Reverb kit made its way from Weston Florida, to Canberra Australia via Fedex international economy (5 days from door to door). The box was very well packed and everything survived the trip intact.

All components are individually bagged and labeled. Marsh Amplification provided a detailed Bill Of Materials and everything checked off against the BOM except for one resistor (82 Ohms instead of 82K Ohms). I sourced a replacement locally for a total cost of less than 10 cents. Full marks for attention to detail here.

I believe that the kit was originally sourced from Mojotone, with a few added extras from Marsh including the Vibrolux Reverb face plate and the build guide (Mojo don't sell a Vibrolux kit at the time of writing.)

The transformers are made by Heyboer, but you can also choose Mercury Magnetics as an upgrade if you want to spend the extra coin. The Power Transformer has multiple taps on the primary winding for international AC power standards (110V, 210V, 220V, 230V, 240V). Other components include:

I believe that the kit was originally sourced from Mojotone, with a few added extras from Marsh including the Vibrolux Reverb face plate and the build guide (Mojo don't sell a Vibrolux kit at the time of writing.)

The transformers are made by Heyboer, but you can also choose Mercury Magnetics as an upgrade if you want to spend the extra coin. The Power Transformer has multiple taps on the primary winding for international AC power standards (110V, 210V, 220V, 230V, 240V). Other components include:

- Orange Drop and TAD capacitors

- Xicon carbon composition resistors (faithful to the original spec)

- Accutronics reverb tank

- Switchcraft jacks

- Vintage-correct cloth covered wire.

- Valves from JJ (3 x 12AX7, 2 x 12AT7, 1 x GZ34) and Electro Harmonix (2 x matched 6L6GC).

I chose to go with 2 x Weber 10A125 Alnico speakers as an upgrade from the standard ceramics.

I spent a stupid amount of time researching and agonising over speaker choice to find no real consensus on the "best" choice for a blackface Vibrolux. It proves the old adage that "opinions are like A&*#@holes, everyone has one!"

If I don't like the sound after a decent break-in period I will change them out for something else and flip these on the 'bay.

Wednesday, 11 April 2012

Hello

This blog serves to document my project to safely build and debug a working valve guitar amplifier. As someone with no prior background in electronics and who until recently didn't understand the difference and relationships between volts, watts, amperes, ohms, and farads, it's been a steep learning curve to get to the point where I'm confident in my ability to succeed with this project.

The general advice for people starting out in guitar amp building is to build a low-powered (5W or less) practice amp such as a Fender Tweed Champ or an AX84. While this is good advice, I chose to ignore it because:

The general advice for people starting out in guitar amp building is to build a low-powered (5W or less) practice amp such as a Fender Tweed Champ or an AX84. While this is good advice, I chose to ignore it because:

- I don't want or need another low-powered small amp at home.

- I was looking for a challenging project that would take me more than a weekend to complete.

- I have wanted a blackface-era Fender amp for some time having played through one or two of them in my younger days. They don't come up too often for sale in Australia and when they do the prices are through the roof. Rolling my own sounded like a good way to go.

- I have previously built a couple of guitar pedals, rewired guitars, and years ago used to solder RS-232 cables for computer terminal installations, so I'm confident in my practical skills.

- I'm a glutton for punishment.

I chose to go with a kit from Marsh Amplification in Florida USA. Mike and Denise Marsh provide a detailed build guide with good photos and diagrams and also email support (which I'm hoping that I don't need to call on too often). I'm also getting great support and encouragement from the members at the Aussie Guitar Gearheads forum and progress pics will also be posted there.

Wish me luck.

Subscribe to:

Posts (Atom)